-

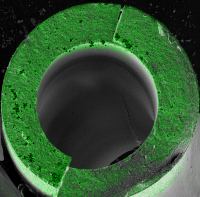

STAMI-SMI Professor Curtis's Lab Grows Natural Polymer Brushes from Surfaces Enzymatically

New work reported from the labs of SMI Professor Jennifer Curtis (School of Physics) introduces a versatile platform to grow ultra-thick, dense hyaluronan (HA) polymer brushes from surfaces using immobilized fragments of enzyme-rich bacterial membranes. This new method provides a path to improved biocompatibility and dynamic control of biointerfaces that potentially can be grown in vivo or regenerated after wear. The research was published in Nature Communications under open access (Nat. Commun. 2019, 10, 5527).

-

Solar Cells from STAMI Members Reach the International Space Station for Testing

Polymer and Perovskite solar cells fabricated in the labs of COPE Prof. Bernard Kippelen (Electrical and Computer Engineering) and COPE, GTPN Prof. Zhiqun Lin (Materials Science and Engineering) have been taken to the International Space Station (ISS) for testing in the harsh space environment as part of the MISSE-12 mission.

-

STAMI-COPE Co-Director Carlos Silva Elected to the Class of 2019 American Physical Society Fellows

STAMI-COPE Co-Director Carlos Silva, Professor in the School of Physics and the School of Chemistry and Biochemistry, has been elected to the 2019 Class of American Physical Society Fellows "[f]or the groundbreaking development of ultrafast laser techniques for probing the transient photophysics of electro-optical and excitonic materials leading to novel and unique insights into charge-separation and carrier generation in organic photovoltaic systems." Congratulations, Professor Silva!

-

STAMI-COPE Professor Shannon Yee Developing Thermoelectric Polymers for Personal Climate Control

STAMI-COPE Professor Shannon Yee and his team of Georgia Tech researchers are developing polymer-based thermoelectric (TE) materials for wearable devices to help people feel warmer or cooler on demand. The polymer TE materials could either harvest body heat to generate electricity or be used to produce a cooling sensation by hooking up a flexible battery to the circuitry.

-

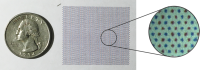

Metal Oxide-infused Membranes Could Offer Low-Energy Alternative For Chemical Separations

CRĀSI member Prof. Mark Losego and GTPN member Prof. Ryan Lively are working on membranes that could separate chemicals without using energy-intensive distillation processes in a wide variety of products including gasoline, plastics, and food. The latest work, published in Chemistry of Materials and sponsored by the Department of Defense and the National Science Foundation, outlined a process for taking a polymer-based membrane and infusing it with a metal oxide network. The resulting membrane is far more effective at standing up to harsh chemicals without degrading.

-

Electrochromic Polymers Advanced in the Lab of GTPN and COPE Professor John Reynolds

A serendipitous discovery by Graduate Student Dylan Christiansen led to polymers that quickly change color from completely clear to a range of vibrant hues — and back again. The work could have applications in everything from skyscraper windows that control the amount of light and heat coming in and out of a building, to switchable camouflage and visors for military applications, and even color-changing cosmetics and clothing. It also helps fill a knowledge gap in a key area of materials science and chemistry.

-

Safer Electrochromic Inks Developed in STAMI-GTPN Professor Reynolds's Lab

Electrochromic films synthesized in the labs of STAMI-GTPN and STAMI-COPE Professor John Reynolds change their colors with the flick of a switch. Now they can be applied more safely thanks to an innovative chemical process that makes them water soluble. They can be sprayed and printed, instead of being confined behind safety implements to handle volatile and toxic fumes.

-

STAMI Students Ditullio and Tremblay Win School of Chemistry and Biochemistry Safety Awards

STAMI Graduate Students Brandon Ditullio and Marie-Helene Tremblay recently received the 2019 William Emerson Safety Awards for impactful contributions to the safety culture in the School of Chemistry and Biochemistry. Winners are nominated by members of their research groups and members of the School of Chemistry and Biochemistry. Thanks and Congratulations Brandon and Marie-Helene!